- HOME

- Business Overview

- Research and Development

S-Tech — New surface modification technology

In this day and age where the diverse needs of the market and company circumstances are changing rapidly, our company stands by the slogan "Put yourself in your customers shoes and continue to improve" as a base as we tackle various research and development projects.

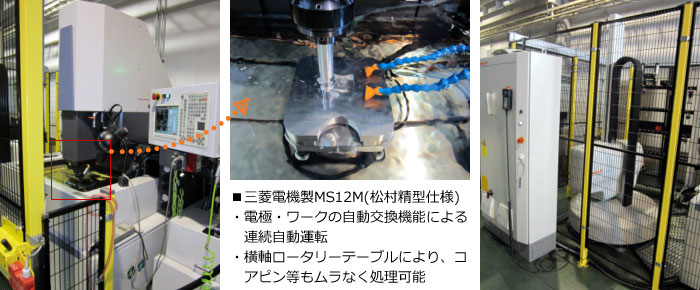

Currently, we are focusing on the commercialization of S-Tech, our new proprietary surface modification technology, which is based on the "Development of surface treatment technology for die casting molds through the optimization and sophistication of electrical discharge gradient film generation technology," which was selected for the 2010 Strategic Foundational Technology Improvement Support Operation by the Ministry of Economy, Trade and Industry. We have moved to the final stage of "providing a prototype to customers" → "evaluation" → "improvement."

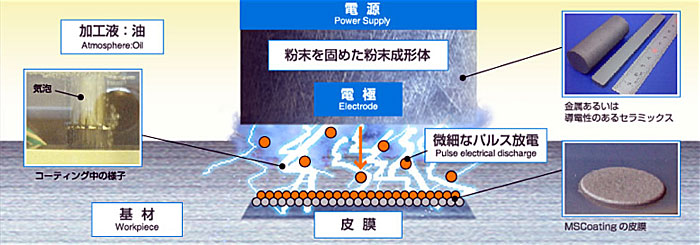

S-Tech is an abbreviation for SSM-Tech, which stands for Strategic Surface Modification Technology. This is a surface treatment technique that has been developed specifically for metal molds based on Mitsubishi electric's "MSCoating" electrical discharge surface treatment technology.

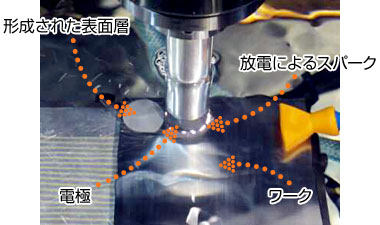

- Pulse discharge heats up the electrode material and the base material (at a range of a few micrometers from the surface).

- Oil explosively vaporizes due to the electrical discharge, which moves the melting electrode to the base material.

- The discharge is configured to occur around 10,000 times per second, and cladding is formed.

Formed surface layer

電極の形状が

そのまま転写される

①Deformation of the workpiece due to thermal strain is small.

Due to the pulse discharge, the heat effect zone is limited to a small area (a few micrometers) of the surface being processed, leaving the rest of the workpiece at a normal temperature.

This forms a strongly bonded surface layer.

The mixed layer is formed when the melted electrode material is transferred to the workpiece.

③Partial surface treatment is also possible.

Forming the electrode in the shape of the area to be processed makes processing of the desired areas possible without masking them off.

④In oil processing using Computer Numerical Control (CNC)

It is possible to correctly repeat the process through the use of CNC, and in oil processing makes it possible to form a stable coating without any oxidation.

Increase the life of mold parts

We apply this treatment to mold parts and portions that are required to be resistant to melting, wear and peeling due to heat, and provide prototypes, while continuing our research and development with the goal of providing long lasting mold parts.

- ■Die casting molds … Prevents galling of form and gating portions

- ■Shell core molds … Prevents wear due to blowing.

- ■Low pressure casting molds … Prevents wear of the core print due to the shell core.

Developing new areas of application

We are currently moving forward in other areas where the special characteristics of S-Tech can be applied.

Developing the quantitative methods for evaluating and assuring surface treatment technology

Our research project "Development of a combined-cycle testing machine to estimate the service life of molds for an aluminum casting production line, and establishment of a guideline for the estimate" was selected for the 2012 Toyama Prefecture Innovation Creation Research Project. Using the results of this project the quantitative value and assurance of S-Tech treatment will be possible as from 4/2013. (planned)